What is a DPF (Diesel Particulate Filter)? A Comprehensive Guide

|

Time to read 10 min

|

Time to read 10 min

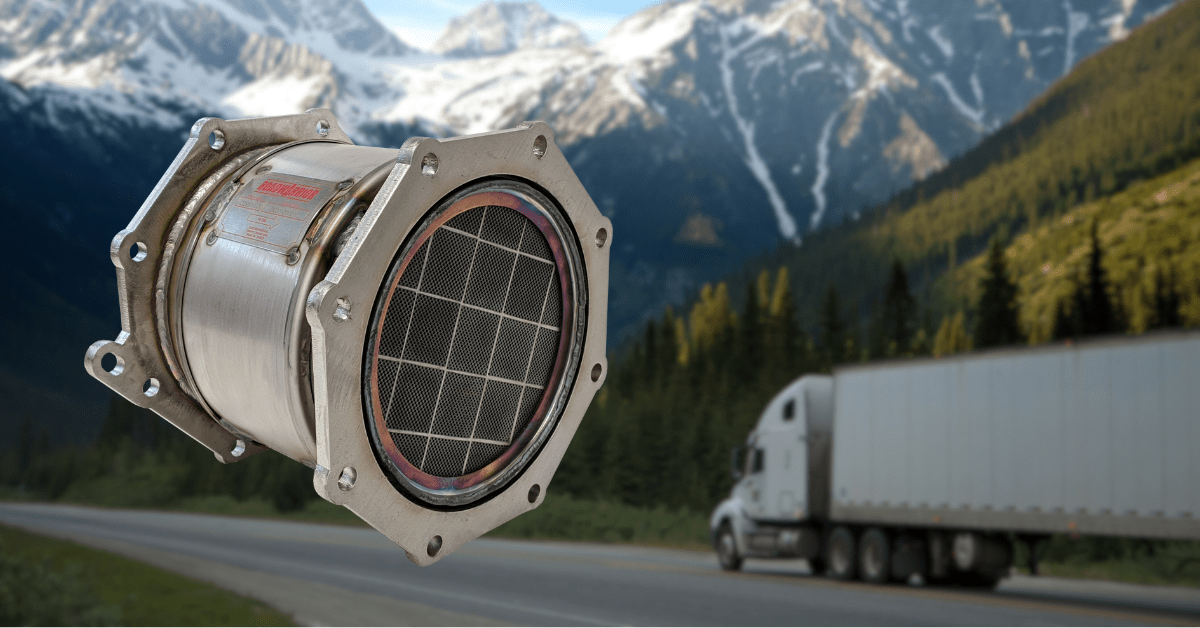

Diesel engines are renowned for their power, fuel efficiency, and durability. However, they produce particulate matter (PM) as a byproduct of combustion, which can harm air quality and public health. Enter the Diesel Particulate Filter (DPF)—a crucial component designed to reduce emissions and keep diesel engines environmentally compliant. In this article, we’ll explore the history of the DPF, its function, how it works, and essential maintenance tips to ensure optimal performance.

The concept of diesel particulate filtration dates back to the 1970s when air quality regulations began to tighten in response to growing concerns over pollution. However, it wasn’t until the early 2000s that DPFs became widespread.

Legislation such as the European Union's Euro 4 and the U.S. Environmental Protection Agency (EPA) standards mandated reduced particulate emissions from diesel engines. As a result, DPFs became standard on most diesel vehicles to meet these stringent regulations, helping to significantly lower particulate emissions globally.

A Diesel Particulate Filter is a honeycomb-like structure made from materials like silicon carbide or cordierite. It’s designed to trap and store soot particles from the exhaust gases, preventing them from being released into the atmosphere.

Over time, the trapped soot accumulates, and the DPF needs to undergo a process called regeneration to burn off these particles. There are three main types of regeneration:

The primary role of a DPF is to reduce the particulate matter emissions produced by diesel engines. By capturing soot particles, the DPF:

You will need some type of software to manually perform a force regen. We highly recommend truck owners explore OTR Performance Diagnostic to perform a forced regen.

Proper DPF maintenance is essential for avoiding costly repairs and ensuring long-term performance. Here’s how to keep your DPF in top shape:

Drive at Highway Speeds Regularly

Frequent short trips at low speeds can lead to soot buildup. Driving at highway speeds allows for passive regeneration, helping to clear the filter naturally.

Use High-Quality Diesel Fuel

Low-quality fuel can produce excessive soot, increasing the strain on your DPF. Opt for cleaner diesel blends to minimize deposits.

Monitor Warning Lights

Pay attention to the DPF warning light on your dashboard. Ignoring it can lead to a clogged filter, reduced engine performance, or even permanent damage.

Schedule Regular DPF Cleaning

Over time, ash buildup in the DPF can’t be removed through regeneration alone. Professional DPF cleaning services use specialized equipment to restore the filter's efficiency.

Avoid Frequent Engine Idling

Idling produces low exhaust temperatures, preventing regeneration and contributing to soot accumulation.

A failing or clogged DPF can lead to various performance issues. Watch out for these symptoms:

If you notice these signs, it’s crucial to address the issue promptly to avoid further damage to your vehicle.

The DPF is not just an emissions control device—it’s a vital component for meeting environmental regulations and ensuring diesel engines operate efficiently. While maintaining a DPF requires effort, the benefits far outweigh the costs. A well-maintained DPF improves fuel economy, prolongs engine life, and contributes to a cleaner environment.

Understanding the importance of the Diesel Particulate Filter and maintaining it properly can save you from expensive repairs and ensure your vehicle runs efficiently. Whether you're a truck driver, fleet manager, or diesel enthusiast, keeping your DPF in top condition is key to compliance, performance, and sustainability.

Looking to clean or replace your DPF? Contact DPF Discounter for expert advice and services tailored to your needs!

If your DPF filter is cracked, don't forget to check out DPF Discounter for high-quality yet affordable DPF filters.

DPF cleaning is the process of removing accumulated soot, ash, and other particulate matter from a Diesel Particulate Filter (DPF) to restore it to optimal performance. DPFs are designed to capture and store exhaust soot to reduce emissions from diesel engines. However, over time, the filter can become clogged with soot and ash, affecting engine performance, increasing fuel consumption, and potentially leading to costly repairs if not addressed.

Passive Regeneration : This occurs when the exhaust temperature reaches high enough levels (typically during highway driving) to burn off the soot automatically. However, it doesn’t remove the ash, which accumulates over time.

Active Regeneration : When sensors detect that the filter is filling up, the engine’s ECU (Engine Control Unit) injects extra fuel into the exhaust to increase the temperature and burn off the accumulated soot.

Forced Regeneration : This method uses diagnostic tools to initiate the cleaning cycle by raising exhaust temperature to clear out the soot. It’s typically done in a repair shop.

Off-vehicle DPF Cleaning : The filter is removed from the vehicle and cleaned using specialized machines that blow compressed air, heated fluids, or ultrasonic waves to remove soot and ash.

Regular DPF cleaning can extend the life of the filter and help maintain vehicle performance, as well as avoid costly repairs or replacement.

Removing a Diesel Particulate Filter (DPF) for cleaning involves several steps. This can vary slightly depending on the vehicle make and model, but here’s a general guide to the process. Be sure to check your vehicle’s service manual for specific instructions, as some models may require special tools or procedures.

- Socket wrench set

- Ratchet and extension

- Penetrating oil or lubricant spray

- Safety glasses and gloves

- Floor jack and jack stands (if necessary)

- DPF removal tool (if required for your vehicle model)

- New gaskets or seals, if needed for reinstallation

- Park on a Level Surface : Ensure the vehicle is parked on a flat surface with the parking brake on.

- Allow the Engine to Cool : Since the DPF gets very hot during operation, let the vehicle cool completely to avoid burns.

- Raise the Vehicle (if needed) : If the DPF is located under the vehicle, use a floor jack and jack stands to lift the car and access the exhaust system.

- Locate the DPF : The DPF is generally located in the exhaust system between the engine and the muffler.

- Apply Penetrating Oil : Spray penetrating oil on the bolts and clamps around the DPF to loosen any rust or corrosion, which will make removal easier.

- Disconnect Sensors : DPFs often have temperature and pressure sensors attached. Carefully disconnect these to avoid damaging them.

- Remove Mounting Bolts and Clamps : Use the socket wrench to remove any bolts or clamps securing the DPF in place. Keep track of these parts for reinstallation.

- Carefully Lower the DPF : Some DPFs are heavy and may require a second person or a support stand. Carefully remove it from the exhaust assembly, ensuring you don’t damage nearby components or wiring.

- Take the DPF to a Cleaning Service : Many shops use specialized equipment to clean DPFs thoroughly. These services may include compressed air, thermal cleaning, or ultrasonic cleaning, which is more effective than basic cleaning methods.

- Replace Gaskets or Seals : If your vehicle has gaskets around the DPF, replace them before reinstalling.

- Reconnect and Secure : Reattach the DPF using the mounting bolts and clamps, reconnect any sensors, and ensure everything is tightened securely.

- Lower the Vehicle : If you raised the vehicle, lower it carefully.

Use a Diagnostic Tool : Some vehicles may require a DPF reset using an OBD-II diagnostic tool, especially if the DPF warning light was triggered.

After reinstalling, start the vehicle and check for any error codes. If you’re unsure about any step, a professional mechanic can perform the DPF removal and cleaning.

We have made detailed step by step guide for Freightliner Cascadia and Cummins X15 DPF removal and installation on our How-To Video page.

➡️ How to remove Freightliner One Box And DPFs - A Step-by-step Guide

➡️ How to Install Freightliner One Box and DPF filter - A Step-By-Step Guide

➡️ How to Remove Cummins X15 DPF and DOC (Kenworth, Peterbilt, Freightliner, Volvo) - Step by Step

➡️ How to Install Diesel Particulate Filter (DPF) and Diesel Oxidation Catalyst (DOC) for Cummins X15

Cleaning DPF filter at home isn't recommended. However, some people attempt to use pressurized warm/hot water to clean the inlet side of the DPF filter. Even though the soot on the inlet side of the DPF surface can be cleaned up, the ash and soot trapped inside the DPF filter vessels will not be broken down. We did a air restriction test after the cleaning with this "home cleaning" method, and the air restriction barely changed. In conclusion, save the headache, and seek a professional DPF filter cleaning facility near you to get the DPF filter tested and cleaned professionally.

Here is a video to show you

Why Pressure Washing Your DPF is a Costly Mistake: A Technician's Insight

The frequency of DPF cleaning depends on your driving habits. Long highway drives reduce the need for frequent cleanings, but city driving with frequent stops and starts can lead to quicker clogging. On average, it's recommended to do a parked regeneration every 1-2 weeks, and do a DPF filter cleaning every 100,000 to 150,000 miles.

It is always recommended to clean your DOC along with your DPF filter when you get a professional DPF filter cleaning service.

There are several signs to watch for that indicate your Diesel Particulate Filter (DPF) may need cleaning:

- Most vehicles have a DPF warning light on the dashboard. When this light comes on, it typically means that the filter is becoming clogged and requires regeneration or cleaning.

- A clogged DPF can restrict exhaust flow, which affects engine performance. You may notice a lack of power, slower acceleration, or increased fuel consumption.

- When the DPF is full of soot or ash, the engine works harder, resulting in higher fuel consumption.

- If you notice your vehicle is frequently going into regeneration mode (where it tries to burn off soot automatically), it could mean the DPF is becoming clogged faster than it can clean itself.

- In some cases, a full DPF may result in dark exhaust smoke, as the exhaust flow becomes restricted, and unburned fuel is released from the exhaust system.

- Clogged DPFs can cause excessive exhaust temperatures, as the engine tries to burn off the accumulated soot. This might lead to further damage if not addressed.

- You may notice a strong, acrid smell from the exhaust, especially during regeneration attempts. This odor is often caused by the filter trying to burn off excess soot unsuccessfully.

If you notice any of these signs, it’s a good idea to have your DPF checked and cleaned as soon as possible to avoid more serious (and costly) issues.

At Diesel Emissions Specialists, we are equipped with industry-proven thermal DPF cleaning equipment. Here are the DPF cleaning process:

- Visual inspection – check for damage & evidence of upstream issues.

- Wire/Pin test for plugged cells.

Measure the airflow of the filter.

Measure the filter weight .

Check for cracks in the brick using the built-in light .

Record the pre-clean inspect & benchmark results into DPF Cleaning Record software.

Remove as much loose material as possible from the filter before baking.

- Load the filters into the oven.

- Set the filter cycle based on the filters being cleaned.

- Using the redesigned new touchscreen user interface.

- The baking cycle usually runs overnight.

- Carefully remove the hot filters from the oven.

- Place the filters on the Cool-Down Cart .

- Accelerated the cooling process safely.

- Uses high-velocity, heated air .

- Most filters dry in 20 minutes .

- An adapter kit is available for many odd and irregularly shaped filters.

- Exclusive to the Aqueous package.

- Wire/Pin test for plugged cells if needed.

- Measure & compare the airflow of the cleaned filter to determine effectiveness.

- Measure & compare the cleaned filter weight to see how much soot was removed.

Record post-clean inspect & benchmark results into DPF Cleaning Record software.

The Thermal cleaning process usually is about a day. The baking cycle is often completed overnight and then it takes a few hours for the filters to cool down.

At Diesel Emissions Specialists, we charge $350 per DPF filter cleaning, $500 per DPF & DOC combo cleaning, $350 per SCR cleaning, $1,200 per Freightliner One Box cleaning (including the 2 DPF filters).

For fleet customers, please contact us for volume pricing.

For customers that needs our shop labor for DPF filter removal and installation, please contact us to get an estimate.