How to Replace Oil Pressure Sensor on Cummins X15

|

Time to read 2 min

Published on

|

Time to read 2 min

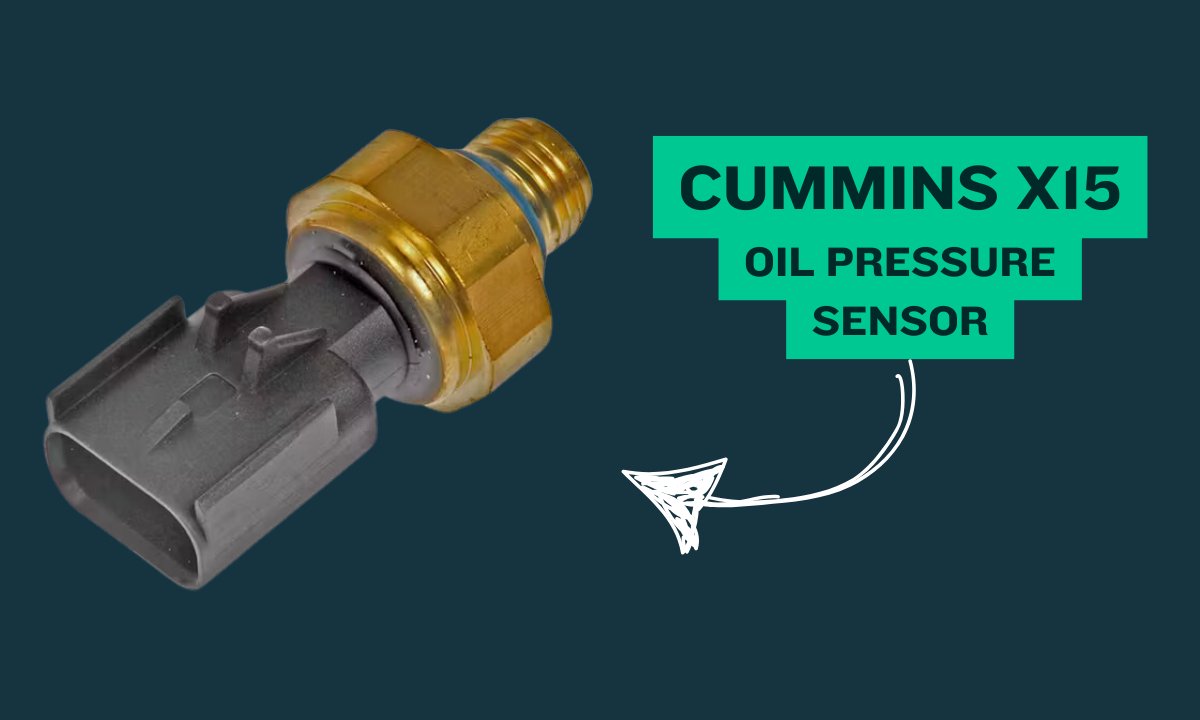

Maintaining the peak performance and longevity of your truck hinges on proactive component management. The oil pressure sensor, a vital component in Cummins X15 engines, is central to this goal. This guide provides a step-by-step walkthrough for identifying signs of a malfunctioning oil pressure sensor and effectively replacing it.

Before diving into the replacement procedure, it's imperative to recognize potential issues with your oil pressure sensor. Here are some key indicators to be mindful of:

Warning Light on the Dashboard: If your oil pressure warning light illuminates but your engine oil levels are normal, the sensor might be faulty.

Erratic or Inaccurate Gauge Readings: Sudden spikes, drops, or fluctuating oil pressure readings could indicate a failing sensor.

Low Oil Pressure Warning Despite Proper Oil Levels: Consistent low-pressure warnings even after checking oil levels may point to sensor issues.

Engine Performance Problems: A faulty oil pressure sensor might send inaccurate signals, potentially leading to poor engine performance or triggering limp mode in modern vehicles.

Oil Leaks Around the Sensor: Visible oil around the base of the sensor could mean it’s damaged or improperly sealed.

Difficulty Diagnosing Oil Pressure Problems: If troubleshooting doesn’t reveal other mechanical causes, the sensor itself could be the issue.

Precise knowledge of the sensor's location is fundamental to the replacement process. In an international truck, the sensor is typically situated behind the ECM (Engine Control Module). It's worth noting that this location can be somewhat constrained, requiring extra care during replacement.

Now, let's proceed with the precise steps to replace your oil pressure sensor

Proactively replacing the oil pressure sensor when you observe signs of leakage is a prudent approach. Delaying replacement until complete sensor failure can result in your truck shutting down, leading to inconvenience and potentially more extensive damage.

Maintaining your truck's oil pressure sensor is indispensable for consistent performance and safety. This guide empowers you with the knowledge needed to identify issues with your Cummins X15 oil pressure sensor and replace it effectively. Routinely inspecting and promptly addressing signs of trouble are essential to ensuring your truck's reliability on the road.We recommend you to watch this video from YouTube: How to Tell Oil Pressure Sensor is Bad on Semi Trucks

Bridging the gap between premium emission products and the customers who need them the most, all at unbeatable prices.

Address:

1120 High Ave SW

Canton, Ohio 44707 USA

Hours: Mon-Fri: 9am - 5pm

Parts: order@dpfdiscounter.com

Service: service@dpfdiscounter.com

Phone: 330-573-5396

© 2025, DPF Discounter All rights reserved.